A Johnson Outboard Wiring Diagram provides a detailed visual guide for understanding electrical systems, essential for installation, troubleshooting, and repairs. It outlines connections, components, and color-coded wires, ensuring safe and efficient system operation.

1.1 Importance of Wiring Diagrams for Johnson Outboards

Wiring diagrams are crucial for understanding and maintaining Johnson outboard electrical systems. They provide clear visuals of connections, enabling accurate troubleshooting and repairs. These diagrams help identify components, color-coded wires, and circuits, ensuring safe and efficient system operation. Without them, diagnosing issues or performing installations would be challenging, leading to potential errors or safety hazards.

1.2 Overview of Schematic Johnson Outboard Wiring Diagram PDF

A schematic Johnson Outboard Wiring Diagram PDF offers a detailed, visual representation of electrical systems, including wire connections, circuits, and components. It provides color-coded wiring, making it easier to identify and trace wires. The PDF includes step-by-step instructions and symbols, ensuring clarity for technicians and DIYers. This resource is essential for troubleshooting, repairs, and installing electrical components accurately and safely.

Key Components of the Wiring Diagram

Johnson Outboard Motors feature intricate electrical systems, including ignition, trim, and gauges. These systems rely on wiring diagrams to ensure proper connections, power distribution, and component functionality.

2.1 Electrical Systems in Johnson Outboard Motors

Johnson Outboard Motors rely on complex electrical systems, including ignition, trim, and gauge circuits. These systems are powered by batteries and controlled through wiring harnesses. Color-coded wires simplify identification, while diagrams provide clear connections for components like starters and gauges. Proper installation and troubleshooting require a detailed understanding of these systems, ensuring reliable boat operation and safety.

2.2 Understanding the Wiring Harness and Connectors

The wiring harness in Johnson Outboard Motors serves as the backbone of electrical connectivity, linking components like ignition, trim, and gauges. Marine-grade insulation protects wires from corrosion. Connectors ensure secure, water-resistant connections. Color-coded wires simplify identification. Diagrams detail harness layouts, aiding in installation and troubleshooting. Proper connector maintenance is critical for preventing electrical failures and ensuring reliable motor performance.

Where to Find Reliable Wiring Diagrams

Reliable Johnson Outboard Wiring Diagrams can be found in official service manuals, online repositories, and forums. Websites like Boats.net and specialized marine forums offer accurate, detailed PDFs.

3.1 Official Johnson Outboard Service Manuals

Official Johnson Outboard Service Manuals are the most reliable source for accurate wiring diagrams. These manuals, available on Johnson’s official website or authorized dealers, provide detailed schematics, high-resolution images, and step-by-step instructions. They cover various models and years, ensuring compatibility and correctness for DIY repairs and professional maintenance. Essential for safe and effective electrical system work.

3.2 Online Repositories for Free Wiring Diagrams

Online repositories offer free wiring diagrams for Johnson outboards, providing detailed schematics and downloadable PDFs. Websites like Boats.net and forums dedicated to marine engines host these resources, covering various models and years. These diagrams are valuable for DIY enthusiasts and professionals, ensuring compatibility and accuracy for repairs and installations. Always cross-verify for specific model accuracy.

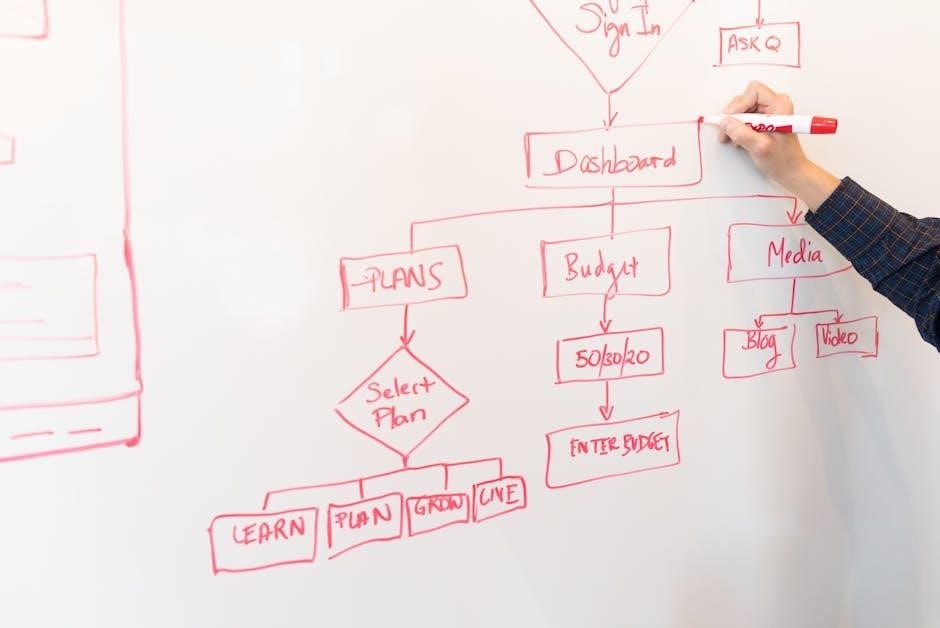

How to Read and Interpret the Wiring Diagram

Understanding the wiring diagram involves identifying color-coded wires, symbols, and connections. It helps trace circuits, locate components, and comprehend electrical flow, ensuring accurate diagnostics and repairs.

4.1 Color Coding for Wires in Johnson Outboards

Johnson Outboards use color coding to identify wire functions, ensuring easy recognition. Red typically signifies battery positive, while yellow marks ignition circuits. White/black and green/black denote tachometer and trim functions, respectively. This standardized system enhances safety, simplifies diagnostics, and prevents wiring errors during repairs or installations, making electrical troubleshooting more efficient and reliable.

4.2 Common Symbols and Notations Used

Johnson Outboard wiring diagrams use standardized symbols to represent components. Circles denote connectors, rectangles represent electrical devices, and lines signify wires. Abbreviations like “IGN” for ignition and “BAT” for battery are common. These symbols ensure clarity, making it easier to interpret and troubleshoot wiring systems effectively, even for those with limited electrical expertise.

Troubleshooting Common Electrical Issues

Johnson Outboard wiring diagrams aid in troubleshooting by identifying faults through color-coded wires and symbols. Regular maintenance prevents corrosion and damage, ensuring reliable electrical system performance.

5.1 Identifying Faults Using the Wiring Diagram

The wiring diagram is a crucial tool for identifying faults in Johnson Outboard electrical systems. By referencing the diagram, technicians can trace wiring connections, identify color-coded wires, and locate faulty components. Symbols and notations guide the diagnosis process, ensuring accurate repairs. Regularly checking connectors and wires against the diagram helps prevent corrosion and damage, maintaining reliable performance.

5.2 Tools and Techniques for Diagnostic Procedures

Essential tools for diagnosing Johnson Outboard wiring issues include multimeters, circuit testers, and wiring diagram PDFs. Techniques involve checking voltage, continuity, and verifying connections. Use color-coded wires to trace circuits and identify shorts or opens. Regularly inspect connectors for corrosion and ensure proper insulation. Referencing service manuals and diagrams helps pinpoint faults efficiently, ensuring accurate repairs and maintaining system reliability.

Safety Precautions When Working with Wiring

Always disconnect the battery and ensure power is off before handling wiring. Use insulated tools to prevent shocks. Regularly inspect wires for damage or corrosion to avoid hazards.

6.1 Essential Safety Practices for Electrical Systems

When working with Johnson outboard wiring, always disconnect the battery to prevent power surges. Use insulated tools to avoid electrical shocks. Ensure all components are de-energized before inspection or repair. Regularly inspect wires for signs of wear or corrosion, and replace damaged sections promptly. Follow the wiring diagram to identify live circuits and handle them with care. Proper grounding and circuit protection devices are crucial to safeguard against electrical hazards. Always refer to the official service manual for specific safety guidelines tailored to your Johnson outboard model. Wearing protective gear, such as gloves and safety glasses, is recommended to minimize risks during electrical work. By adhering to these practices, you can ensure a safe working environment and prevent potential electrical failures.

6.2 Pre-Installation Checks for Wiring Components

Before installing Johnson outboard wiring components, inspect all wires for frays, cuts, or corrosion. Verify connectors are clean and secure, ensuring no loose connections. Cross-reference the wiring harness with the diagram to confirm compatibility and proper routing. Check for any signs of water intrusion, as moisture can compromise electrical integrity. Test all circuits for continuity using a multimeter to ensure there are no open or short circuits. Replace any damaged or corroded components to prevent future malfunctions. Properly label and organize wires according to the schematic to simplify installation and future maintenance. Ensure all components are rated for marine environments to withstand exposure to saltwater and humidity. By conducting thorough pre-installation checks, you can ensure a reliable and durable electrical system for your Johnson outboard motor.

Installation and Maintenance Tips

Adhere to the wiring diagram for precise connections. Use marine-grade materials and secure all components to prevent damage. Regularly inspect wires for corrosion and wear, ensuring longevity and reliability.

7.1 Step-by-Step Guide for Wiring Harness Installation

- Plan the installation using the schematic Johnson outboard wiring diagram PDF for accuracy.

- Mount the wiring harness securely to avoid damage from heat or vibration.

- Connect wires according to the color-coding and symbols in the diagram.

- Use marine-grade connectors and sealants to protect against corrosion.

- Test each connection to ensure proper functionality before finalizing.

7.2 Regular Maintenance to Prevent Corrosion and Damage

Regularly inspect wiring for signs of wear or corrosion. Clean connections and apply marine-grade lubricants to protect against moisture. Ensure all components are securely fastened to prevent vibration damage. After exposure to saltwater, rinse and dry the wiring system. Follow the schematic Johnson outboard wiring diagram PDF for specific maintenance recommendations tailored to your model.

Differences Between Johnson and Evinrude Wiring Diagrams

Johnson and Evinrude wiring diagrams differ in configurations due to distinct electrical systems. Color coding and connector layouts vary, requiring model-specific schematics for accurate repairs and installations.

8.1 Comparative Analysis of Wiring Configurations

Johnson and Evinrude wiring diagrams reveal distinct configurations, with differences in terminal connections, color coding, and component layouts. Johnson systems often emphasize straightforward, universal connectors, while Evinrude may incorporate more specialized components. These variations impact installation and troubleshooting, necessitating careful study of model-specific schematics for accurate repairs and upgrades.

8.2 Compatibility of Wiring Components Across Models

While Johnson and Evinrude wiring components share some compatibility, differences in connectors and harness designs can limit interchangeability. Universal connectors in Johnson systems may not align with Evinrude’s specialized configurations, requiring adapters or custom solutions. Always consult the specific wiring diagram for your model to ensure compatibility and avoid electrical mismatches.

DIY vs. Professional Wiring Repairs

DIY wiring repairs can save costs but require precise diagram knowledge. For complex issues, professional technicians ensure safety and reliability, especially with critical systems like Johnson outboards.

9.1 When to Attempt DIY Repairs

DIY repairs are suitable for minor issues like replacing fuses or inspecting connections, using a wiring diagram for guidance. Ensure you have basic tools and knowledge to avoid further damage. However, complex electrical problems or system overhauls should be left to professionals to maintain safety and system integrity.

9.2 Scenarios Requiring Professional Assistance

Complex wiring issues, such as damaged harnesses or malfunctioning sensors, require professional expertise. If the wiring diagram indicates advanced repairs or system overhauls, seek a certified technician. They possess the specialized tools and knowledge to ensure proper repairs, preventing further damage and ensuring compliance with safety standards and manufacturer recommendations.

Johnson Outboard Wiring Diagrams are crucial for safe and efficient system management. Always follow safety practices and maintain wiring regularly. Future trends will enhance reliability and performance.

10.1 Summary of Key Takeaways

Johnson Outboard Wiring Diagrams are essential for understanding electrical systems, troubleshooting, and maintenance. They provide detailed schematics, color coding, and symbols to guide repairs. Regular inspection and adherence to safety practices are crucial. Future trends will focus on enhancing reliability and performance, ensuring Johnson outboards remain a top choice for boating enthusiasts.

10.2 Future Trends in Johnson Outboard Wiring Systems

Future trends in Johnson Outboard Wiring Systems will focus on advanced digital integration, improved corrosion resistance, and simplified diagnostics. Enhanced materials and automated systems will boost reliability and performance. Smart wiring solutions and eco-friendly designs will dominate, ensuring Johnson outboards remain at the forefront of marine technology and user convenience.