This manual provides comprehensive guidance for the Bridgeport Series I milling machine, covering installation, operation, maintenance, and safety protocols. It serves as an essential resource for both novice and experienced operators.

1.1. Overview of the Bridgeport Series I Milling Machine

The Bridgeport Series I milling machine is a versatile and durable tool designed for precision milling operations. It features a robust construction, variable spindle speeds, and interchangeable heads, including the J-Head and 2J2-Head, catering to diverse machining needs. This machine is ideal for both standard and complex milling tasks, making it a staple in workshops and manufacturing environments. Its reliability and adaptability have made it a preferred choice among professionals and enthusiasts alike.

1.2. Purpose and Scope of the Manual

This manual is designed to guide users through the safe and effective operation of the Bridgeport Series I milling machine. It covers installation, maintenance, and troubleshooting, ensuring optimal performance. The scope includes detailed instructions for machine controls, head adjustments, and preventive maintenance, providing a comprehensive resource for operators to master the equipment’s capabilities and maintain its longevity.

Installation and Setup

This section provides a detailed guide for installing and setting up the Bridgeport Series I milling machine, ensuring proper configuration and readiness for operation.

2.1. Pre-Installation Requirements

Before installing the Bridgeport Series I, ensure a stable foundation, proper electrical connections, and compliance with safety standards. The area must be clean, level, and free from obstructions to guarantee optimal performance and operator safety.

2.2. Step-by-Step Installation Guide

Begin by unpacking and positioning the machine on a level surface. Connect power and ensure all controls are accessible. Adjust the spindle nose and table feed mechanisms according to the manual. Tighten all fixtures securely and test the spindle rotation. Follow the manufacturer’s guidelines for integrating with systems like the Acu-Rite III DRO. Ensure proper alignment and calibration before initial operation.

2.3. Integration with Other Systems

Integrate the Bridgeport Series I with systems like the Acu-Rite III DRO for enhanced precision. Ensure compatibility with CNC controls by following installation guides. Connect power and data cables securely, aligning the machine with external devices. Test communication between systems to confirm functionality. Refer to the manual for specific protocols and settings to achieve seamless integration and optimal performance.

Operating Instructions

Understand the machine controls, safety protocols, and operational best practices for the Bridgeport Series I. Follow step-by-step guides for setup, function, and troubleshooting to ensure efficient milling operations.

3.1. Machine Controls and Functions

The Bridgeport Series I features intuitive controls for spindle speed, feed rates, and table movement. The J-Head and 2J2-Head variants offer precise milling operations. Always wear safety glasses and avoid loose clothing. Follow manual instructions for changing spindle RPM and adjusting table feeds. Proper control operation ensures accurate machining and-safe working conditions. Regularly review safety guidelines to prevent accidents.

3.2. J-Head and 2J2-Head Controls

The J-Head and 2J2-Head controls on the Bridgeport Series I milling machine provide precise operation of spindle speed and table feed. The J-Head offers mechanical variable speed, while the 2J2-Head includes additional features for enhanced control. Always refer to the manual for specific instructions on adjusting these controls to ensure optimal performance and safety during milling operations.

3.3. Mechanical and Variable Table Feed

The Bridgeport Series I milling machine features both mechanical and variable table feed mechanisms. The mechanical feed uses a gear-driven system for precise, consistent movement, ideal for rigid operations. The variable feed allows adjustable control via a handwheel, offering flexibility for fine-tuned machining. Always follow manual instructions for setting these feeds to ensure accurate and safe milling operations, avoiding unintended spindle speed changes.

Maintenance and Repair

Regular maintenance ensures optimal performance and longevity of the Bridgeport Series I milling machine. Routine checks, lubrication, and timely repair of worn parts are essential for smooth operation.

4.1. Routine Maintenance Procedures

Regular lubrication of moving parts, thorough cleaning of the spindle and table, and inspection of belts and gears are crucial. Ensure all alignments are precise and tighten loose components. Follow safety guidelines and refer to the manual for specific maintenance schedules to prevent wear and tear, ensuring optimal machine performance and longevity.

4.2. Troubleshooting Common Issues

Common issues include spindle misalignment, vibration, or feed problems. Check alignment, tighten loose parts, and clean the spindle nose; For motor issues, ensure proper power supply and inspect belts for wear. Address gearbox noises by checking oil levels and replacing worn gears. Always follow safety guidelines and refer to the manual for detailed diagnostic procedures to resolve problems efficiently.

4.3. Parts Replacement and Service

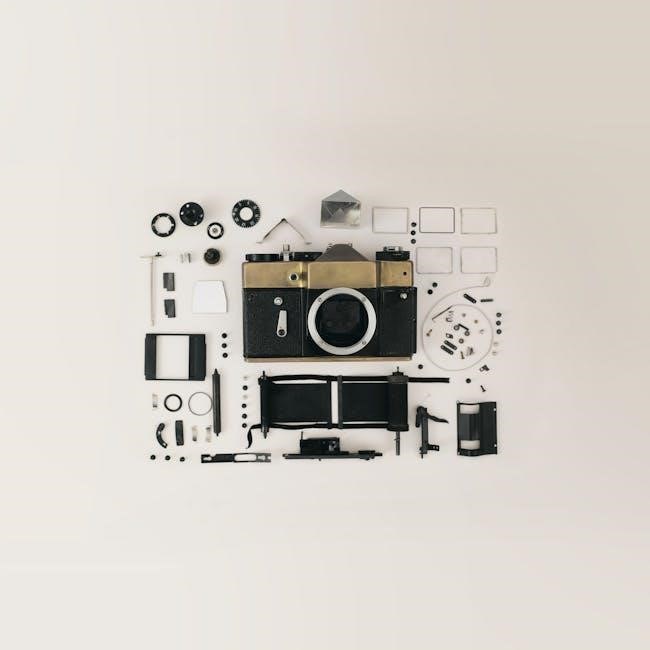

Replace worn or damaged parts promptly to maintain machine performance. Use the detailed parts catalog to identify components. Follow proper disassembly and reassembly procedures, ensuring all bolts are tightened to specified torque values. Always use genuine Bridgeport replacement parts for reliability. Refer to the manual for specific service intervals and guidelines to ensure safe and effective maintenance.

Safety Precautions

Always follow safety guidelines to prevent injuries. Wear protective gear, avoid loose clothing, and ensure proper machine guarding. Adhere to emergency procedures for safe operation and maintenance.

5.1. General Safety Guidelines

Always prioritize safety when operating the Bridgeport Series I milling machine. Wear safety glasses, secure loose clothing, and ensure proper machine guarding. Keep the work area clean and well-lit. Avoid wearing jewelry or gloves that could get caught. Use proper tools for adjustments and follow all operational and maintenance instructions carefully to prevent accidents.

5.2. Protective Equipment and Clothing

Wear approved safety glasses with side shields and industrial safety shoes when operating the Bridgeport Series I. Avoid loose clothing, long hair, or jewelry that could entangle. Use a face mask when handling dusty materials. Ensure proper PPE is worn at all times to minimize risks and prevent injury during machine operation and maintenance tasks.

5.3. Emergency Procedures

In case of emergencies, immediately switch off the machine and evacuate the area if necessary. For fires, use a fire extinguisher rated for electrical or metal fires. If injured, provide first aid and seek medical attention promptly. Report incidents to supervisors and follow proper protocols to prevent further risks and ensure safe machine operation and maintenance.

Parts List and Specifications

This section provides a detailed catalog of parts and specifications for the Bridgeport Series I milling machine, ensuring accurate identification and ordering of components for maintenance and repairs.

6.1. Detailed Parts Catalog

This section offers an exhaustive list of components for the Bridgeport Series I, including spindle assemblies, feed mechanisms, and control systems. Each part is cataloged with specifications and diagrams for easy identification and ordering, ensuring precise maintenance and repair operations. The catalog is organized by function and serial number for quick reference and accuracy.

6.2. Machine Specifications

The Bridgeport Series I features a 9″ x 42″ table size, 16-1/2″ knee travel, and a spindle with speeds from 60 to 4,200 RPM. Equipped with a 1 HP motor, it supports both mechanical and variable table feeds. The machine weighs approximately 1,500 lbs, ensuring stability during operation. These specifications ensure precise milling capabilities for various industrial applications.

Advanced Features and Programming

This section explores advanced features like CNC programming and the Acu-Rite III Digital ReadOut (DRO) system, enhancing precision and efficiency in milling operations. Custom macros allow for tailored functionality, streamlining complex tasks and improving productivity. These tools are essential for optimizing machine performance and adapting to specific operational needs.

7.1. CNC Programming for Bridgeport Series I

The CNC programming manual provides detailed operating guidelines for the Series I milling machine. It covers installation, operation, and maintenance, ensuring precise control over milling, drilling, and boring tasks. The Acu-Rite III Digital ReadOut (DRO) system enhances accuracy, while safety instructions emphasize proper spindle speed management and control usage. This guide is essential for mastering CNC operations on the Bridgeport Series I.

7.2. Acu-Rite III Digital ReadOut (DRO) System

The Acu-Rite III Digital ReadOut (DRO) system enhances precision and efficiency for the Bridgeport Series I milling machine. It provides accurate three-axis position feedback, simplifying complex machining tasks. The system integrates seamlessly with CNC programming, offering a user-friendly interface. Its advanced features ensure precise control, making it an essential tool for achieving high-quality results in milling, drilling, and boring operations. Proper installation and setup are detailed in the manual.

Common Modifications and Upgrades

Popular upgrades include enhancing performance with improved feed systems and customization options for specific machining needs. Upgrading to CNC integration or DRO systems is also common.

8.1. Enhancing Performance

Enhancing performance often involves upgrading the spindle bearings, improving the table feed system, and optimizing the motor for higher torque. Additionally, installing a DRO system like the Acu-Rite III enhances precision and efficiency. Regular maintenance and fine-tuning of components ensure optimal operation and extend the machine’s lifespan. These modifications are widely recommended by experts and users alike.

8.2. Customization Options

Customization options for the Bridgeport Series I include upgrading to CNC programming, installing the Acu-Rite III DRO system, and modifying the machine with aftermarket parts. Users can also add power feeds, coolant systems, or specialized tooling to enhance functionality. These customizations allow operators to tailor the machine to specific tasks, improving efficiency and versatility in various milling applications.

Vintage Restoration Tips

Restoring classic Bridgeport mills involves dismantling, cleaning, and replacing worn parts. Refurbishing the spindle, table, and knee ensures optimal performance. Repainting and lubricating moving components completes the restoration process.

9.1. Restoring Classic Bridgeport Mills

Restoring classic Bridgeport mills requires careful dismantling, cleaning, and inspection of worn components. Refurbishing the spindle, table, and knee ensures precision and durability. Replacing original parts with genuine components or refurbished equivalents maintains authenticity. Sanding and repainting the frame restores its appearance. Lubricating all moving parts and aligning the machine ensures optimal performance. Regular maintenance post-restoration preserves functionality and longevity.

9.2. Preservation of Historical Machinery

Preserving historical Bridgeport machinery involves meticulous documentation, careful cleaning, and storage in controlled environments. Regular lubrication and minimal disassembly prevent corrosion and wear. Using original or era-specific parts maintains authenticity. Engaging with collector communities and museums ensures these machines remain functional and educational for future generations. Proper preservation honors their historical significance and industrial heritage.

Resources and Support

Access official documentation, community forums, and expert advice for troubleshooting, modifications, and maintenance. These resources provide comprehensive support for mastering the Bridgeport Series I milling machine.

10.1. Official Documentation and Guides

The official Bridgeport Series I manual provides detailed installation, operation, and maintenance instructions. It includes parts lists, specifications, and troubleshooting tips. Specific guides for models like BR2J cover mechanical and CNC operations, ensuring comprehensive understanding. Additional resources include CNC programming manuals and Acu-Rite DRO system documentation, offering in-depth support for optimal machine performance and user safety.

10.2. Community Forums and Expert Advice

Active communities and forums dedicated to Bridgeport milling machines offer valuable insights and expert advice. Operators share experiences, troubleshooting tips, and custom modifications. These platforms are ideal for discussing restoration projects, optimizing performance, and resolving technical issues. Engaging with these communities provides access to collective knowledge and practical solutions from experienced users and professionals.

This manual provides a comprehensive guide to mastering the Bridgeport Series I milling machine, ensuring safe and effective operation, maintenance, and troubleshooting for optimal performance.

11.1. Final Tips for Mastering the Bridgeport Manual

- Always prioritize safety by wearing protective gear and following guidelines.

- Regularly perform routine maintenance to ensure optimal machine performance.

- Refer to the manual for specific instructions and troubleshooting common issues.

- Practice with simple tasks before attempting complex milling operations.

- Engage with community forums for expert advice and shared experiences.